Hi guys

Just a quick update on what i have learned over the past few days or so.

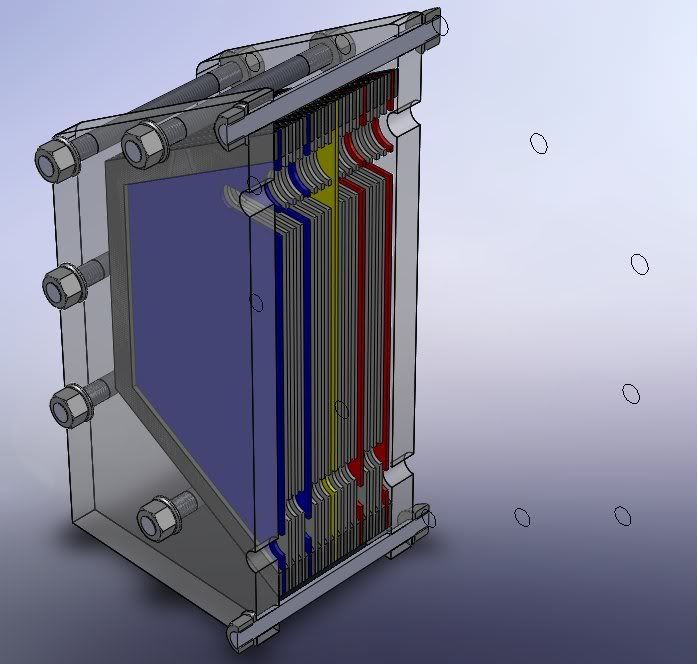

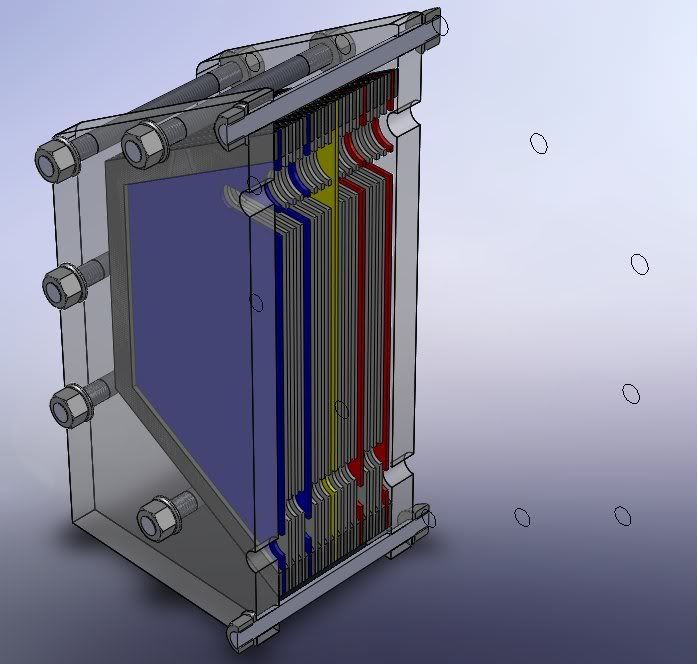

Anyway heres my latest design which i think im going to build first.

let me know what you think. Brief description under the image.

Cell Description:-

You may notice that there are 2 negative on one side of the cell and 2 positive plates on the other side of the cell, and one yellow blanking plate in the middle. This plate has only 1 opening at the bottom for the electrolyte to flow through into the negative chamber. The theory is that negative plates produce Hydrogen and the positive plates produce oxygen thus making the hydrogen output percentage higher because the oxygen is vented out of the other side of the cell.

You also may notice the offset of holes in the neutral plate’s compared the positive and negative plates. This is to slow down and break up the fresh electrolyte from the tank/bubbler. Instead of having a straight through design, this would be very easy for the electrolyte to flow straight through the cell without mixing with the electrolyte in the cell.

I'm not sure if I have explained this very well. Anyway let me know your thoughts.

Gareth

Reply With Quote

Reply With Quote