Hello everyone!

New to the forum, really enjoy reading in on others experiences and appreciate them for being open with their ideals.

I have been into the HHO hobby for a year and half. I'm a fan of "Joe cells" because I had good results with one but haven't replicated it.

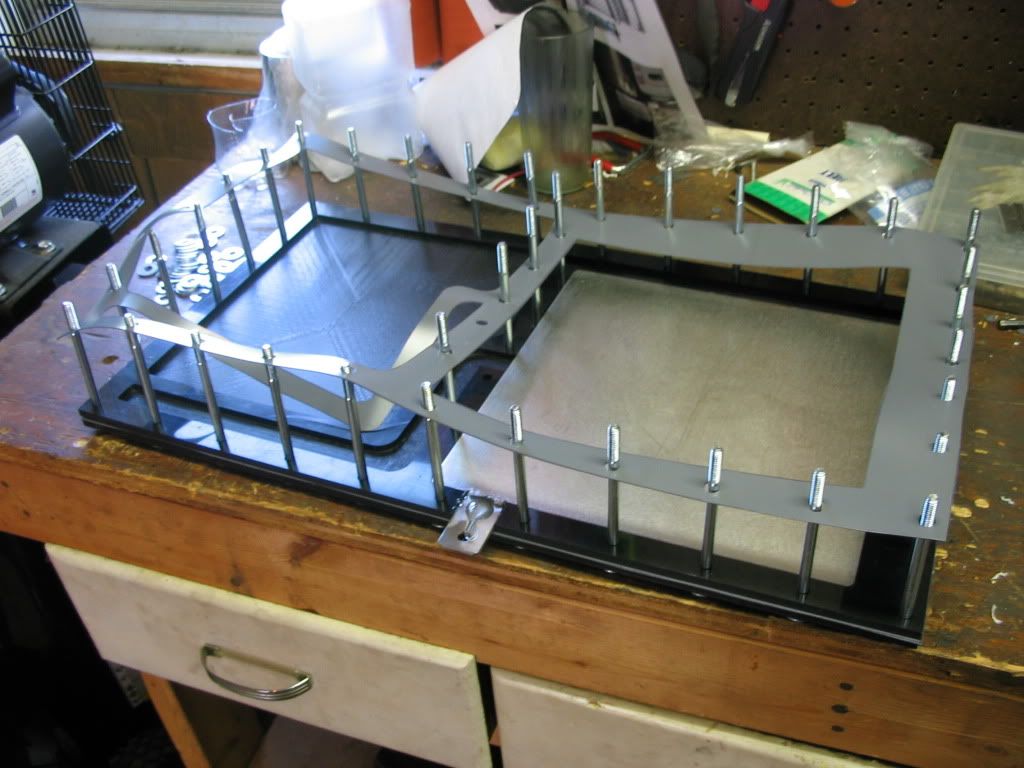

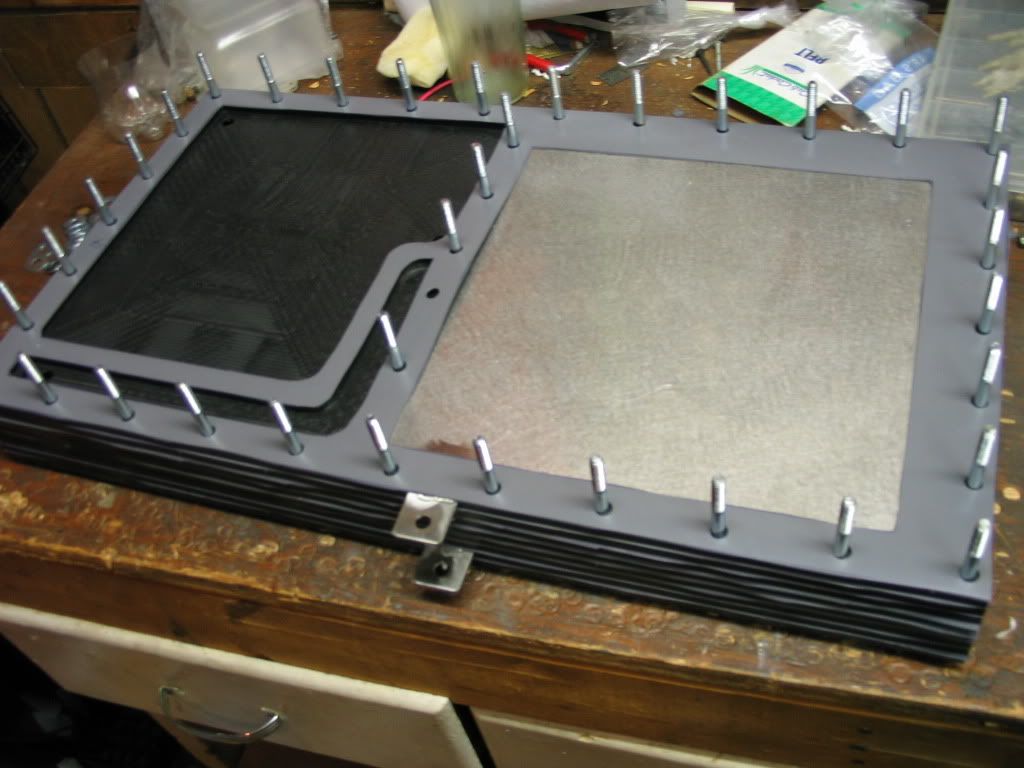

I'm building a "Trucker cell" using 10"x10" 316 plates....075 in. thick, each plate weighs 2.2 pounds. It's a two cell with 4 neutrals each. There is 9.75" of exposed plate area because the plates are supported in a machined plastic housing. Plate spacing is .210 in. maybe far for some but for larger plates, I think it's appropriate. There is a total of 2000 sq in. of applied plate area.

If you look at the pictures below, the plastic housing is has an integrated water tank. Originally this cell was going to be a true "zero current leakage cell" where the water between two plates recirculates in it's own bubbler, never mixing with water from other plates. I canned it and made it a dry cell.

The cost? (Hey honey!? We need to get a second mortgage!...)LOL! I think I flushed down over $1500 dollars for this bad boy.

Here is a plastic housing with one of the "negative" plates with the gasket going down next.

Another housing piece next inline.

It's monkey see, monkey do from here on out.

Here it is on the test bench. Notice the gas exiting up from the plates, through the channel area?

So how did it perform? At 82 amps direct current with no PWM, it pushed 5.9-6 liters a minute. So far a 6.0 MMW was achieved. The highest temp it reached was 105 degrees after an hour of operation. (Outside temp 75 degrees.)

Reply With Quote

Reply With Quote