Originally Posted by

keiththevp

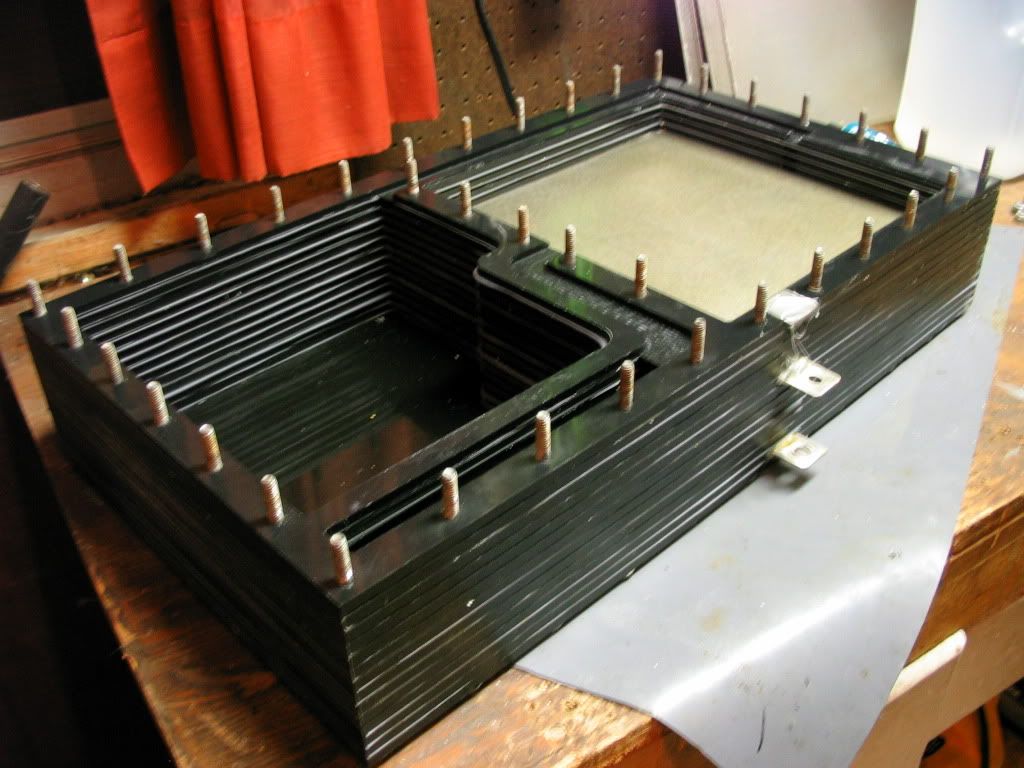

Nice build, what do you use on the power tabs coming out the side so that they do not leak? Also at 70 amps does that thing heat up real bad? I saw the video description of 105 degrees after an hour, but most semi's run 8-12 hours so have you done a long term test to see what the temp tops out at?

Yeah His Tucker cell is a great design.

I wondered about the tabs leaking also. A similar design i had the tabs just sealed from the gasket material but that was with very thin electrodes (and thick soft gaskets). I was thinking using thicker electrodes, you could simple bevel the sides of the tabs at a 60 -70 degree angle to a knife edge, and they might seal without any sealant.

b1jetmech,

I really like that cell to have a reservoir and cell together is real practical to me.

Do you think the beveling might work for a seal with out sealant?

Do you think your MMW is the same for nickle and SS?

When you're one step ahead of the crowd you're a genius.

When you're two steps ahead, you're a crackpot."

Reply With Quote

Reply With Quote

but it's a good experiment.

but it's a good experiment.