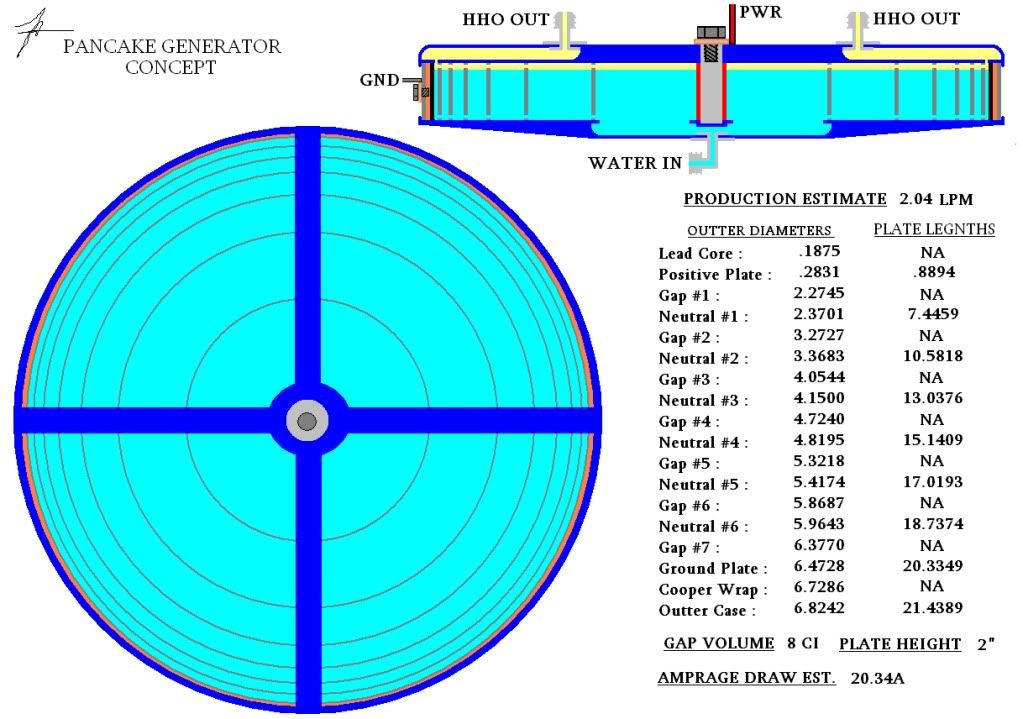

Just wanted to see if anyone has tried anything like this. Get your thoughts before i build my prototype. Its a cylindrical design. Sense amperage is the same through out a cicuit. im using a constain 8 ci with varring gaps to prevent melt down. the lead core and cooper wrap is to promote better conuctivity. ( in theory ) If it works how i think it will, it should produce between 2 LPM while only using 221sq in. of ss. Id appreciate an adice constructive or otherwise. thanks

Reply With Quote

Reply With Quote