Thanks for the help! I can't post pictures tonight, but I will be able to soon.

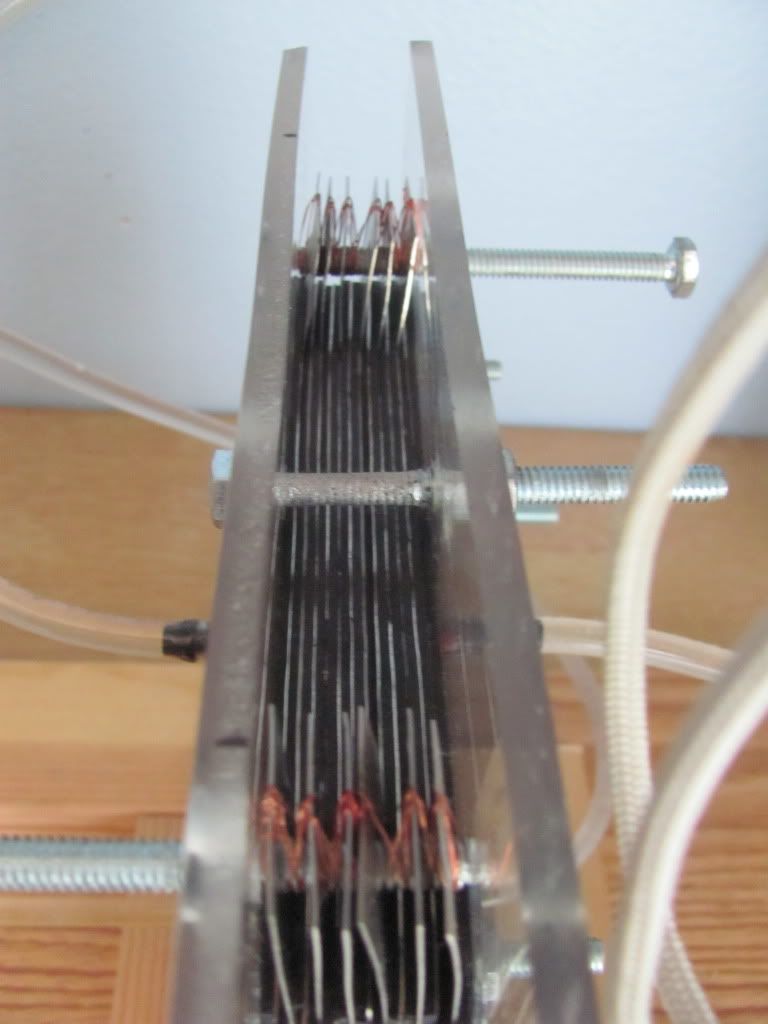

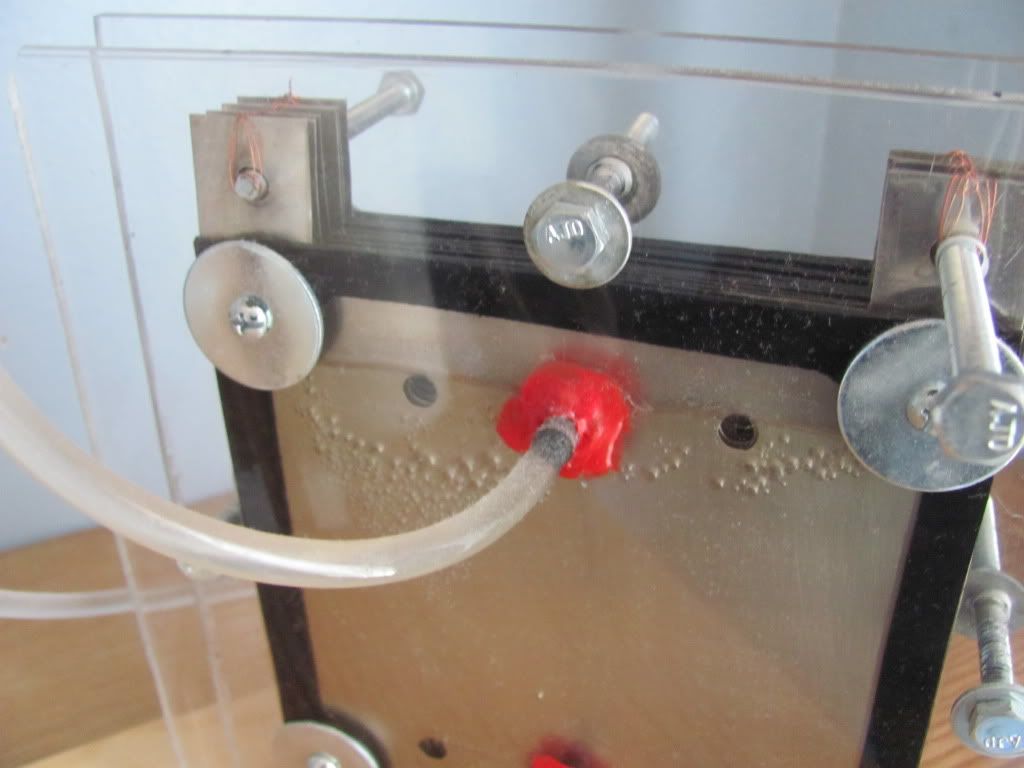

I do have holes in my plates. I'll describe them best I can. I have three on the top and three on the bottom, parallel to each other. Reading around, it seems that putting Weldon 16 around the holes is a good idea. I'm not sure why this is though.

I have sanded my plates, but only a little and I guess sand blasting with nickel slag (or is it copper??) will do better for surface area.

I have no idea what passivating my plates means, so hopefully you can enlighten me

and the electrolyte I use is KOH with VERY small concentration. With the setup I've been using, it would draw way to many amps with even a 1/4 teaspoon per gallon of distilled water.

I've just ordered more parts, 14 more plates and the same gasket. Hopefully I can make this setup more efficient. I hope to save my other cell also and maybe use both at once.

Reply With Quote

Reply With Quote