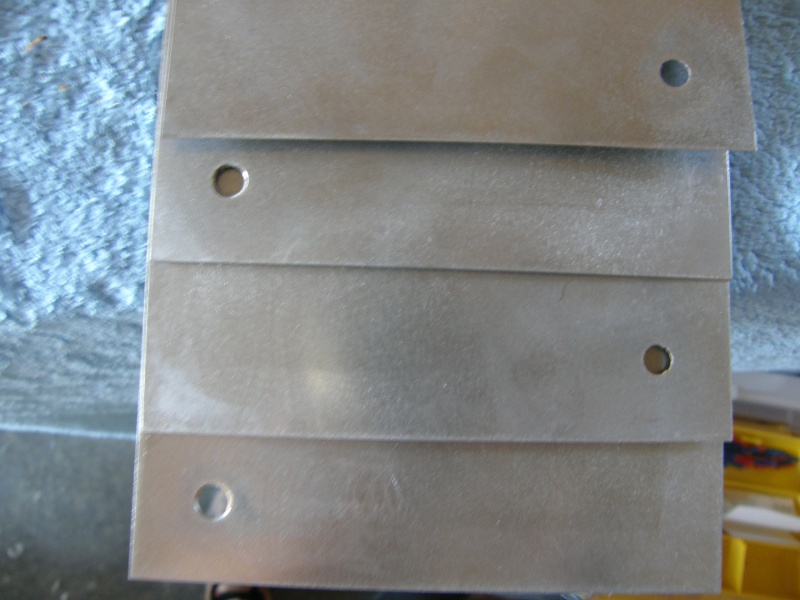

I've seen numerous times that the input holes should be alternating. 1st on the left, next on the right, then left again, and so forth.

I'm unable to do that with the set of plates I have so they're all in line. If you have a flow issue that may be part of it.

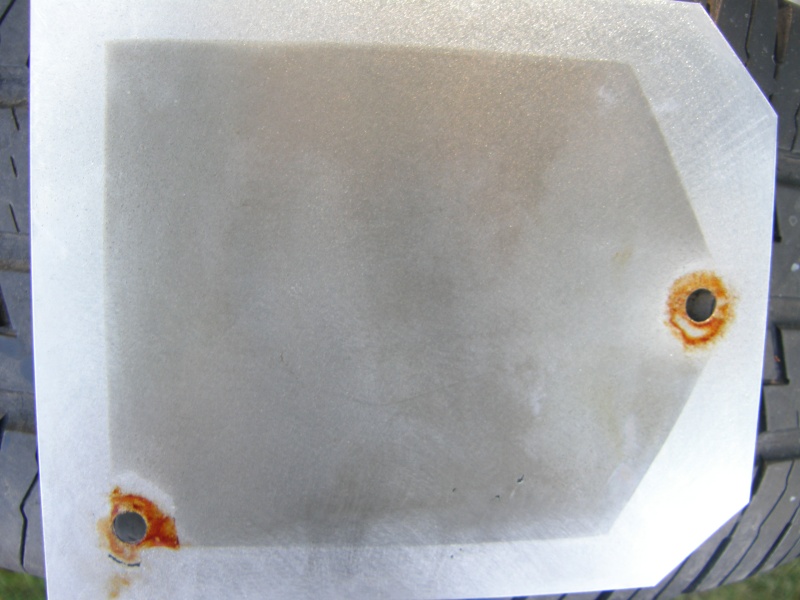

For your brown water - it sounds like either impurities in the distilled water or possibly the plates weren't passivated correctly/enough/contaminants in the passivation. With 316L I wouldn't think there would be much discoloration at all - especially low amps.

First thing I think you should do is check if the flow problem really is the problem. Then Re-mix a fresh batch of electrolyte and re-run Try to keep at the same amperage as before. See if the brown water goes away. Get some Neodymium magnets (they're like $2 at Harbor Freight) and put them on the input line to the reactor - this will tell you if you have magnetic (iron) contaminants leaching from your ss which could be causing your discoloration.

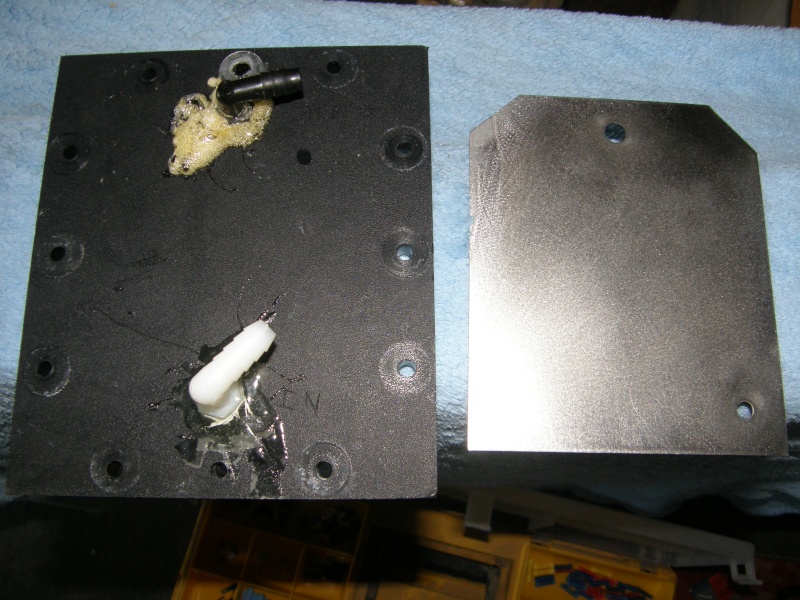

, tomorrow I will do the passivation and assembly of the reactor

, tomorrow I will do the passivation and assembly of the reactor